| .: home .: about .: products .: service .: links .: contacts | |||

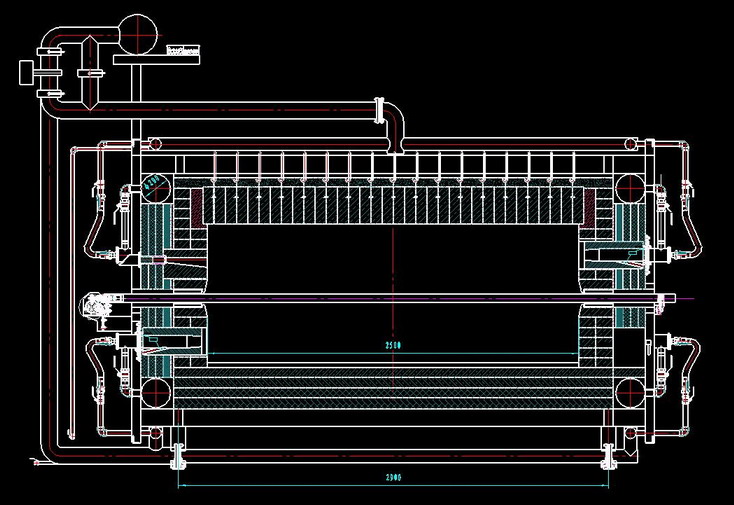

Main equipment instructions and pictures Roller kiln The structure of this roller kiln is box structure. According to functions of each part, the kiln can be divided into 7 parts: steel structure part, refractory material structure part, pipeline system, firing system, gas or oil pipe, transmission system, temperature controlling system, and safety system. Refractory and Heat Preservation Materials of the Kiln The selection of the refractory and heat preservation materials is according to the temperature requirement of different kiln sections. In order to ensure the life of the kiln, higher level than temperature requirement of the materials is to be selected. To reduce the energy consumption, it's better to select materials with low heat conduction coefficient. Refractory and Heat Preservation Materials of the Kiln After filtering impurities by the system and through leveling off the voltage, the gas/oil enters the burner by auto controlled valve. Many burners are interlaced collocated on the body of the kiln, and make the heat source of the kiln even and easy to adjust. 4-8 burners are set at every part of the firing parts. These burners are interlaced collocated to the kiln. 6-8 branch burners are set to be one group, adopting intelligent instrument and upper machine to auto control. Transmission System The whole kiln adopts 45 ° bevel wheel driving method. Every 3 kiln sections forms a driving group, each with a decelerating motor, dragging by motors and with transducer control for tile ' s distance control. The whole kiln consists of 3 groups of transducers for controlling the distance of the tiles. The driving system has the functions as follows: switch of supply power and generating power, group driving swing function, supply power driving function without transducers. It has the advantages of steady, reliable driving, low faults, long life and wide range of speed adjustment.

|

|||

|

|

Copyright © 2008-2010 Beijing Time Progress Technology Development Co., Ltd All rights reserved.

Email: wangweiji@clima.net.cn wangweiji@gmail.com