| .: home .: about .: products .: service .: links .: contacts | |||

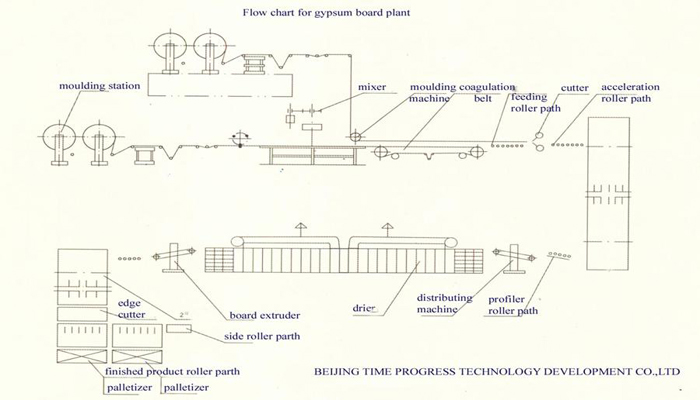

Gypsum board production lineThe gypsum board production line take gypsum plaster for building purpose as the main raw material, mix it with chemical additives and water, continue pours into the space between two shielding tissue, through edge sealing, pressure, coagulation, cut, dry and so on, which make the light building materials. The characteristic of our gypsum board production line include low energy consumption, no pollution and quick construction. It is typical green building material.

Gypsum board production line performance 1. Fireproof: The gypsum board is awkward to fire materials, and its fire-resistant time limit can be up to 1-4 hours 2. The density gypsum is low, while making gypsum board, the board body has been added the reduced weight materials. 3. Constructing: The gypsum board is slim panel, and the commonly used thickness is 9.5mm and 12mm . Its quality of material is soft, therefore its work ability is superior. 4. Warm-keeping performance: the building warm proof performance is related with the living comfort, while the warm-keeping performance of the material depends on the heat conduction coefficient of the material itself, and the heat conduction coefficient of the material relates to density of the material. 5. Soundproof performance: Theory and practice proved that wall thicker, soundproof performance better. Adopting gypsum board as the partition wall can well solve the problem of insulating against sound. 6. Swell and contractibility: the swell and contractibility of gypsum board very light, in addition, gypsum board is used under the room temperature, so its coefficient of expansion can be ignored.

|

|||

|

|

Copyright © 2008-2010 Beijing Time Progress Technology Development Co., Ltd All rights reserved.

Email: wangweiji@clima.net.cn wangweiji@gmail.com