| .: home .: about .: products .: service .: links .: contacts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

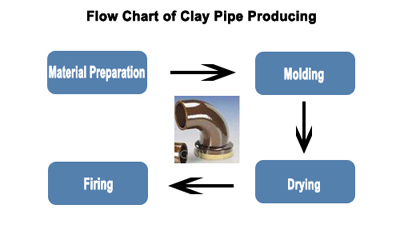

CLIMA clay pipe production line The clay pipe making machine is engaged to produce ceramic clay pipe . In the production line, clay is first ground and mixed with water to the desired consistency. The clay is then molded into pipe moulds with a hydraulic press and shaped clay pipe is fired to achieve strength. Clay pipe making machine is widely use in modern industry. In many regions, the clay pipe is recommended to be used in the connection of the city downcomer net architecture thanks for it's distinct characteristics on anti-rotting of acid and alkali (except hydrofluoric acid) side, high intensity, wear well. As known, in many countries like Saudi Arab, the government prefer adopting clay pipe in future construction.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

Copyright © 2008-2010 Beijing Time Progress Technology Development Co., Ltd All rights reserved.

Email: wangweiji@clima.net.cn wangweiji@gmail.com